Overall Equipment Effectiveness (OEE) is the most common manufacturing metric to understand, measure, and also improve current manufacturing production performance. OEE is expressed as a percentage and is calculated as the product of three other metrics – availability, performance, and quality.

- Availability (%) – actual production time / total planned production time

- Performance (%) – actual production total / target production total

- Quality (%) – good production / total production

Using OEE in Manufacturing Processes

The automation industry primarily offers Overall Equipment Effectiveness in components and tools. There are very few cost-effective, all-encompassing solutions on the market – at least not as an offering from major companies. Popular automation components for OEE range from local visualization products to general purpose PLCs. Many PLC manufacturers tout their products as a key component in an Overall Equipment Effectiveness system. And they absolutely can be that, however they do not arrive with programming - ready to use for OEE. Generally, they simply include the tools and hooks so that you can build your own OEE system around their hardware – or hire a system integrator to build one for you.

To create a ground-up, PLC-based Overall Equipment Effectiveness system, an integrator will expend a high number of engineering hours and pass on the corresponding cost to the end-user. Automation controller manufacturers offer OEE software solutions, but these are very expensive on a work cell level. There are also plenty of software companies that offer canned solutions, but many of these involve significant up-front costs and regular monthly data charges, which is also very expensive.

In short, what seems to be missing in regard to OEE from automation suppliers is a cost-effective, yet scalable, work cell solution that goes beyond visualization. It should come ready to setup and use in a matter of hours – not months... and that’s where Horner Automation Solutions comes in!

Advantages of Using OEE Monitoring Software

Pre-Programmed Overall Equipment Effectiveness Solution with Quick and Simple Set Up

Reports - Log Production Data that's Immediately Available to Every User on the Network

- instantly generate data to use for reports for a process, area, plant, division or your entire enterprise

- collect Overall Equipment Effectiveness data and alarms, downtime reason codes and operator calls

- data to create custom dashboards and reports, and export files exactly how you want them

Results - Single Source Data that's Detailed, Accurate, Timely, and Precise

- operators – meet production targets by improving focus and reacting more quickly to down events

- supervisors – set shift targets using data to analyze and be proactive

- leadership – launch projects, set goals, and compare investments with results

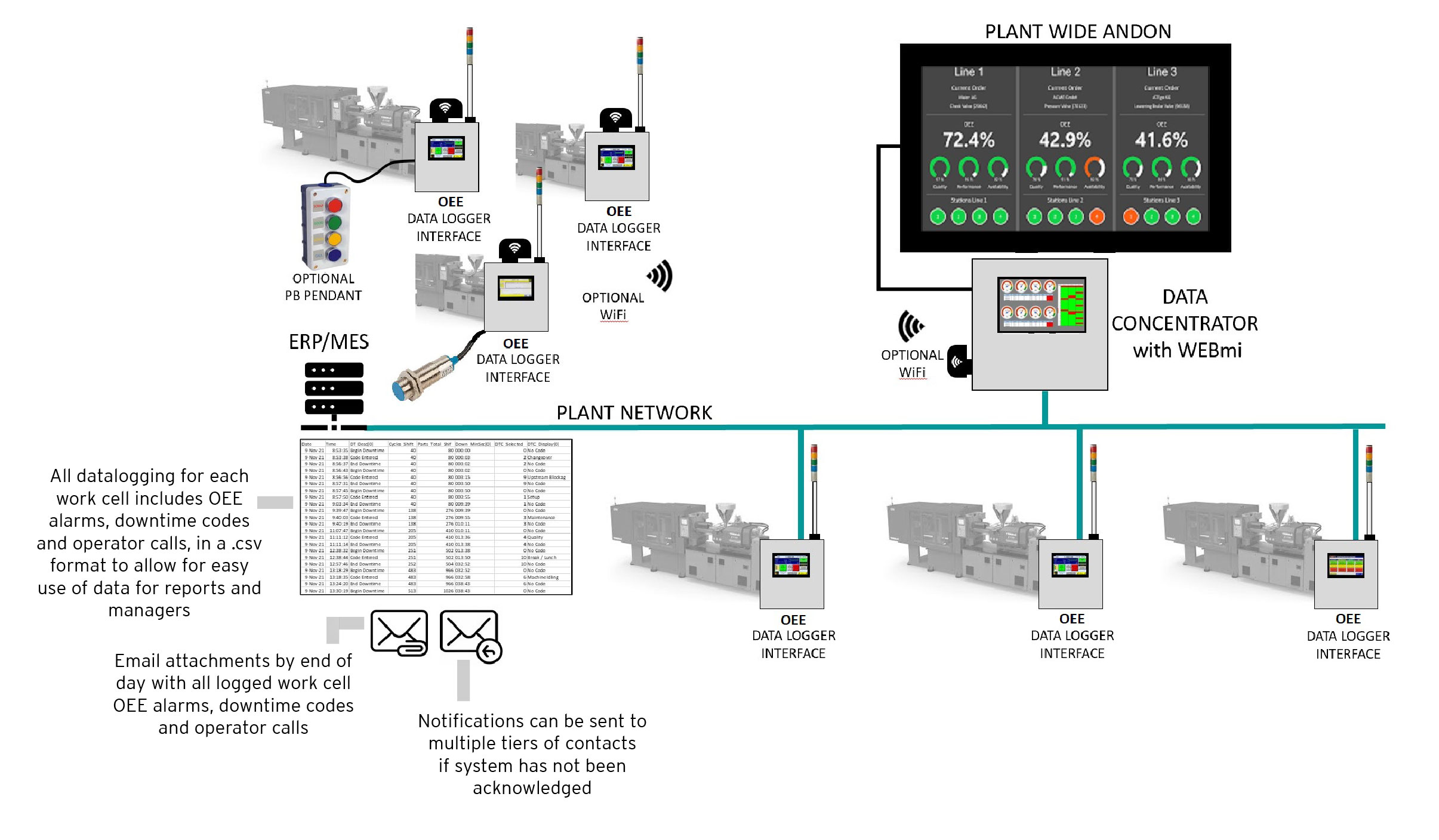

Plant Wide Data Collection and Display

Components of a Typical Horner OEE System

XLW Prime

- manual operator input via HMI or automated input from the machine / process

- plant wide connectivity - via WiFi or Ethernet to a data concentrator

- data storage on microSD memory card

Horner Bundle

- OEE Controller with network connectivity, data storage, power supply, and power disconnect

- 4 color tower light

- prewired terminal blocks for automatic sensor inputs

- protective enclosure

Tower Light (viewable from a distance)

- signal system for "At Goal / Caution / Alarm / Call"

USB and Ethernet Port

- panel mounting options available for - external data file transfers, plant wide LAN connectivity

- also available for individual work cells

WebMI (optional)

- WebMI provides remote visibility and accessibility to data, thus allowing management to monitor operations hourly, daily, weekly, and/or monthly

- plant-wide Andon display

Horner App (optional)

- operators can monitor and control their OEE systems through the Horner App, which is available to download for Android in the Google Play store or for iOS via the App Store

No Specification available